How Does A Snow Blower Work? and Troubleshooting Tips

Snow blower won’t start, runs poorly or line won’t feed? This blog has information on how a snowblower works and offers troubleshooting tips to assist you in diagnosing and repair.

Although snow blowers vary from model to model, they all operate on similar principles. In this blog, we will address how snowblower models can differ, how the engine and drive systems operate and how some common problems can be solved.

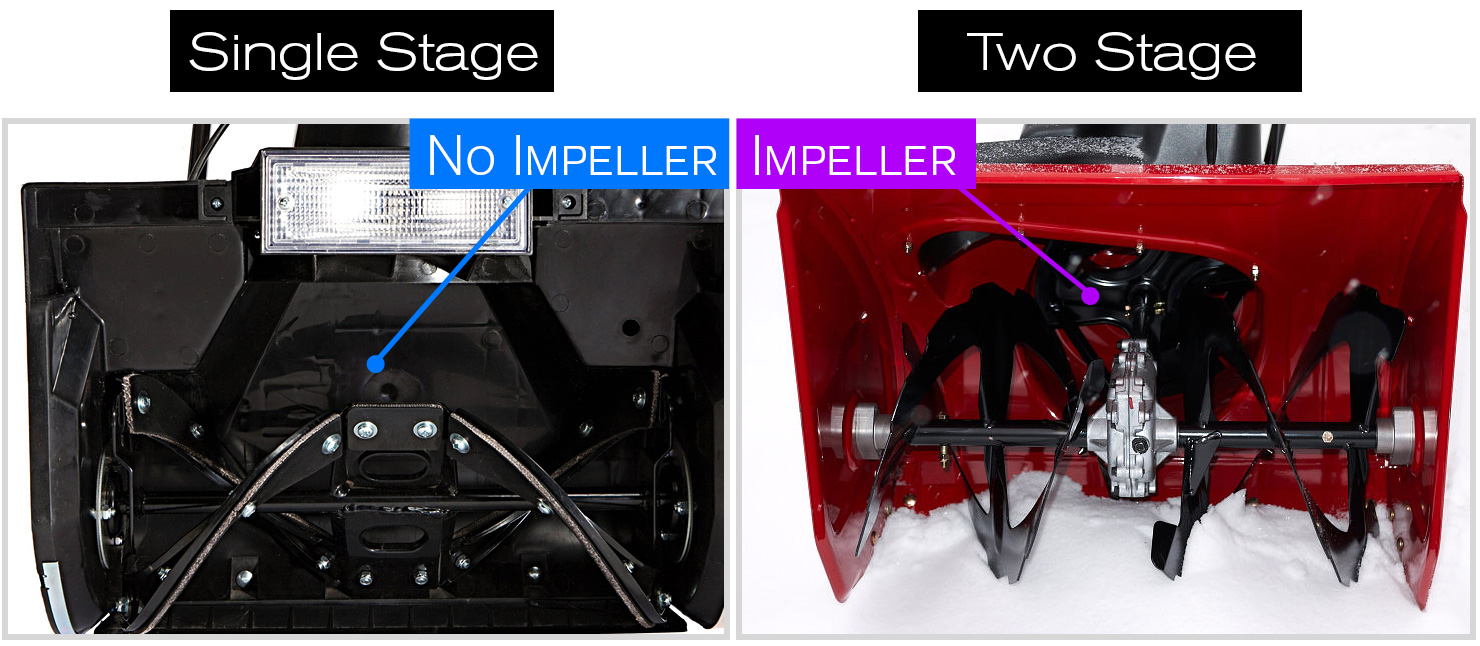

Single-Stage

Most snow blowers are classified as either single-stage or dual-stage. Single-stage models uses one auger to collect and throw the snow and work best on snow that is 8 inches deep or less.

Dual-Stage / Two-Stage

Dual stage snow blowers use an auger to collect the snow and an impeller to throw it. In the first stage, a series of spiral blades is arranged horizontally at the snow intake, with serrated edges along the blades. This arrangement allows for more effective shredding and pushing of compacted snow towards the second stage. The second stage consists of an impeller positioned perpendicular to the front spiral blade axis. The impeller rapidly rotates to discharge the snow. These models can handle snow up to one foot deep or more depending on the size of the auger housing.

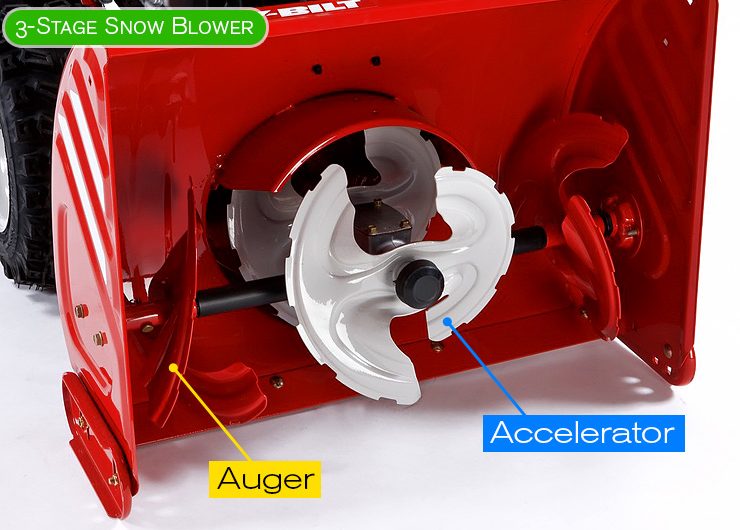

Three-Stage

A three-stage snow blower enhances the spiral blade setup of a two-stage snow blower (first stage). It incorporates an additional vertical accelerator blade (second stage) that, while cutting through the snow, facilitates faster propulsion of the snow into the rear impeller (third stage). This enables quicker discharge of the snow from the working area, resulting in slightly higher clearing efficiency compared to a two-stage snow blower.

Engine

At the heart of every snowblower is the engine. Most single and dual-stage models have a 4-cycle engine. Similar to an automobile engine, 4-cycle engine have a separate sump for oil.

To start the engine, the ignition key must be inserted or turned into position. Larger engines will have an electric start feature that allows the engine to be turned over by using the key or a button. Smaller engines require the use of a starter rope. As the starter rope is pulled, the starter engages the drive cup on the flywheel and rotates the crankshaft. The crankshaft connects to the piston which moves up and down within the cylinder.

As the crankshaft is turned, the rotation of the flywheel and the linear movement of the piston begin the ignition process. The flywheel has permanent magnets built into it and as it rotates past the ignition coil, a magnetic field is created. The magnetic field induces electricity, allowing the ignition coil to send voltage to the spark plug. Meanwhile, the intake valve opens as the piston travels down the cylinder, creating a vacuum which draws fuel and air through the carburetor where it mixes before entering the cylinder. This action is called the intake stroke of the engine.

Next, the compression stroke takes place as the intake valve closes and the piston travels backe up to the top of the cylinder. The spark plug now fires and ignites the compressed fuel and air mixture which forces the piston down, creating the power stroke. The momentum of the spinning flywheel provides enough force to push the piston back up. The exhaust valve opens and the combustion gases exit through the muffler, this is called the exhaust stroke.

The engine will continue to run and repeat these 4-cycle until it is shut off.

Choke and Primer Bulb

Most snow blower engines will have a choke, primer bulb or both to assist with starting. In cold weather, the choke will temporarily restrict airflow through the carburetor, so more fuel can enter the cylinder.

Likewise, a primer bulb draws additional fuel through the carburetor which enters the cylinder before the engine is started. If the engine does not start or it runs improperly, the most likely cause is a defective spark plug or a restriction in the carburetor that prevents the proper fuel and air mixture from entering the engine. The carburetor can be cleaned but it often needs to be replaced.

Fuel

Be aware that snow blower engines are designed to use gasoline with no more than 10% ethanol. Gasoline with higher levels of ethanol can be corrosive and attract water which can cause starting or running problems and may damage the fuel system.

You should store the gasoline in a clean sealed plastic container approved for fuel storage. If equipped, close the vent when not in use and store the container away from direct sunlight. If you anticipate storing the fuel for longer than three months, consider adding a fuel stabilizer when you fill the container.

Auger Drive System

The engine crankshaft extends out the side of the engine and is attached to one or more drive pulleys. On dual-stage models, the impeller is also driven by the engine crankshaft. A single-stage snow blower will have only one drive pulley.

To engage the auger, a spring-loaded idler pulley and belt are used. When the bail arm is engaged, the idler pulley tightens the belt around. The drive pulley and the auger rotates. The auger blades or paddles collect the snow and throw it out of the chute in one motion.

If the belt or paddles wear out, the auger may struggle to throw the snow and if the belt breaks, the auger will not rotate at all.

A dual-stage snowblower often has multiple drive pulleys. One or more belts are used to drive the auger transmission and another belt is used to drive the self-propeled wheels. When the auger drive handle is engaged, a pulley applies tension to the auger drive belts, the transmission engages the auger which rotates much slower than the impeller.

If either side of the auger fails to rotate while engaged, it is likely that the shear bolt has broken. Shear bolts are designed to break if the auger hits a large rock or chunk of ice to prevent damage to the transmission and engine.

Self-Propel System

To operate the self-propel function, the control lever will first need to be set to a designated speed and direction. A drive belt is attached to a drive disc. When the drive handle is engaged, a pulley will apply tension to the drive belt which rotates the drive disc, engages the friction ring and drives the wheels.

A worn or broken belt cable or friction ring will prevent the drive system from engaging properly. Both single and dual stage snow blowers have a scraper blade on the bottom of the auger housing. This component slides along the ground to assist the auger in collecting the snow. Single stage models use the scraper to slide directly on the ground to collect snow very close to the surface. Dual stage models add slide shoes or skids to the sides of the auger housing that allow the user to adjust the position of the scraper blade.If you have a gravel driveway, the scraper should be kept several inches from the ground to prevent rocks from entering the housing. Be aware that scraper blades and slide shoes will wear out over time and will need to be replaced.

Since wet snow can clog the auger housing and shoot, you can use a broom handle or clearing tool to remove an obstruction, but you should never use your hands. To help prevent the snowblower from getting clogged, a polymer spray like snow jet can be used to coat the auger and housing.

Hipastore.com has an extensive selection of instructional blogs to assist you covering topics like part replacement. At hipastore.com, we make fixing things easier.

Revive Your Machine With Hipa Snow Blower Parts

Please let us know if this works and if you have any suggestions or comments. Or you can join HIPA DIY COMMUNITY to feature your passion for repair projects, share your stories with the Hipa family and get help from Hipa.